September 26,

2007

Video Vinyl

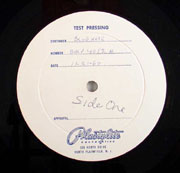

When you read an

explanation of how LPs are made, even a detailed, well-written one, you discover the

limitation of words when it comes to capturing such a multifaceted, technical process.

There are too many steps -- from master to stamper to finished LP -- to visualize exactly

what's happening. YouTube to the rescue. There you will find a ten-minute-long segment from How It's Made, a Discovery

Channel program that documents the manufacture of many different products. In this clip

you can see every part of LP production, from the lacquer coating the aluminum disc to the

heated vinyl oozing from between the stampers. Great stuff.

In a

series of video clips on its website, German reissue label Speakers Corner goes a step

further, revealing some of the fine points of LP production for the audiophile market. It

is slow, methodical work -- the last clip shows LPs being individually inspected and then

re-sleeved -- and Speakers Corner has a lot of experience doing it. Since 1993, the label

has released 346 different titles. Of these, 246 are still in print, which means the

Speakers Corner LP catalog is one of the largest in existence today. The initial pressing

run for all new titles is 1200 copies, with reorders, which use new stampers, occurring on

a near-constant basis. Best-sellers exceed 10,000 copies pressed -- each inspected by

hand.

While digital music slowly abolishes the physical

format in favor of greater convenience, analog playback, the most inconvenient way of

playing recorded music, is thriving. Who would have predicted that for CD's 25th

birthday? Even if you're all digital, these video clips will make you yearn to spin a

record or two.

...Marc Mickelson

editor@soundstage.com